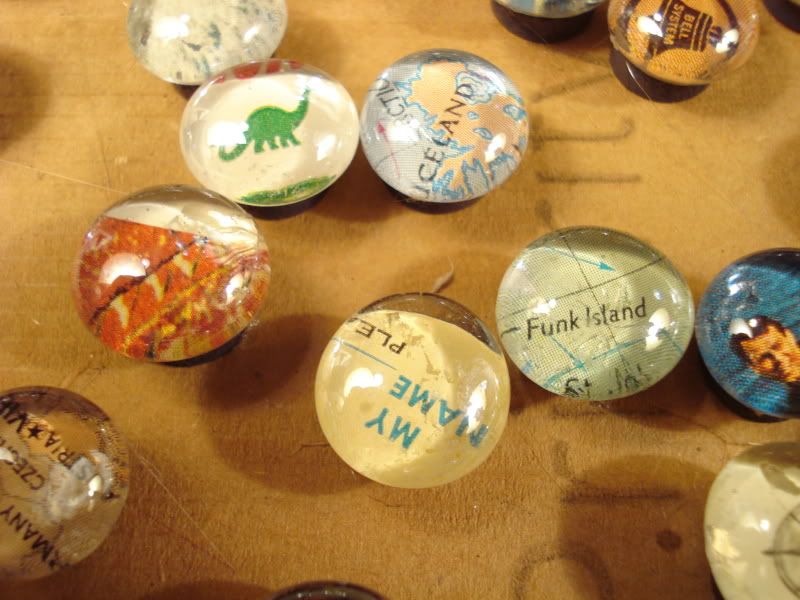

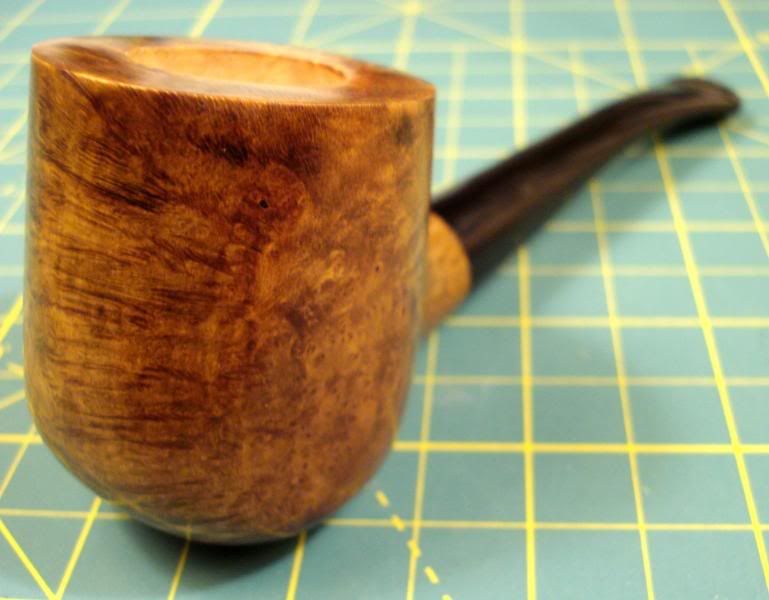

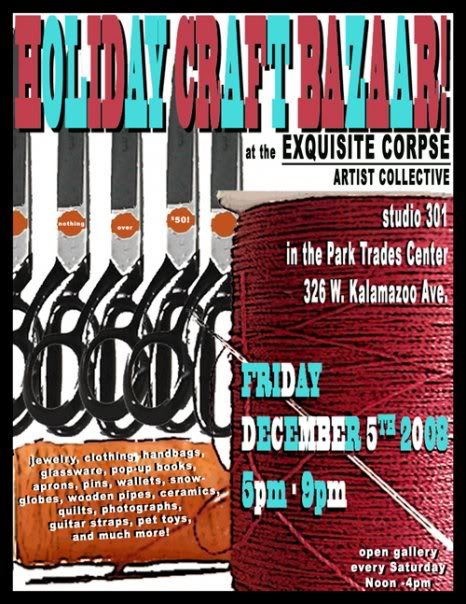

It has been a busy, productive day. I woke early and got to work finishing a new pipe. I'm calling it The Chariot. I also found the time to finish putting together some magnets that Jess got started. We're going to sell them in small batches at the Art Hop. Whatever we have left will then be going up in Jess' shop Umlauf.

I started a new pipe when I finished The Chariot. What a pain in the rear! It will end up a nice little pipe with a curved stem. It started as a nice big pipe with a long stem. There was a flaw in the shank. While I was working it, it literally exploded. Small chunks of briar flying everywhere. So I cut it down to what was left, reshaped the bowl to fit a short shank, and am really quite pleased. Pics when I finish it.

Once the papier mache mix has warmed to room temperature I am going to add another layer on the mannequin Jess will be using at the show.

Here's some of the magnets and the new pipe.